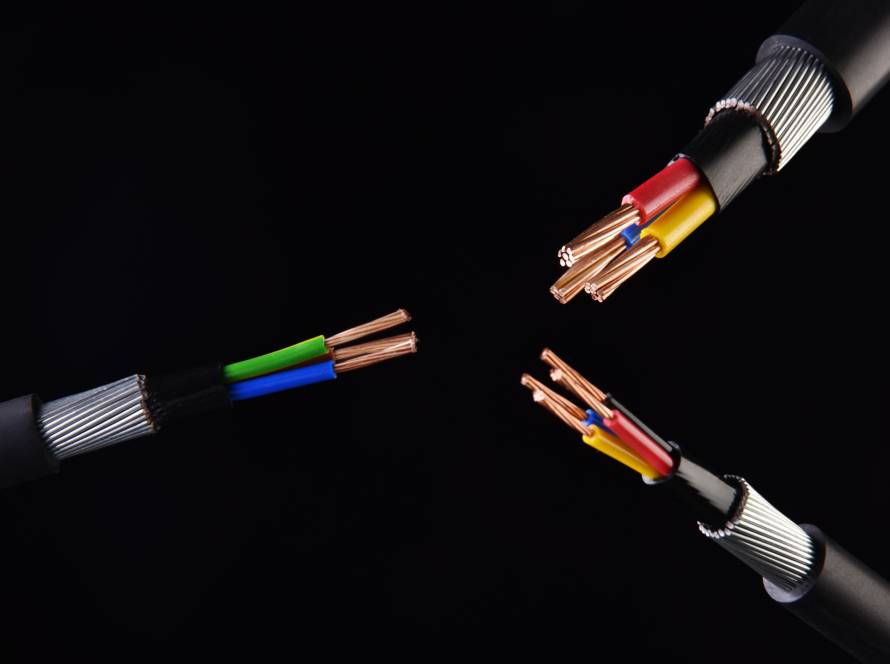

Electric cable conductors require insulation from other conductors and the surrounding environment to avoid short circuits. This is achieved by extruding an insulating layer around the conductor.

In this discussion, we focus on Polyvinyl Chloride (PVC) and Crosslinked Polyethylene (XLPE), which are the two predominant insulation materials utilized in the cable industry.

Why opt for PVC Insulation?

PVC is the most commonly employed insulation material for power cables.

The advantages of PVC insulated cables include:

1) Cost-effectiveness, providing both electrical and physical protection for standard low-voltage building cables.

2) A compact bending radius, facilitating installation in confined spaces.

PVC cables are typically used for general low-voltage applications, such as lighting and in public buildings. However, standard PVC does have some limitations:

1) It has a maximum operating temperature of 70°C.

2) Its resistance to water and environmental stress cracking (ESC) is not as robust.

When is XLPE Insulation the better choice?

When is XLPE Insulation the better choice?

XLPE boasts a maximum operating temperature of 90°C. Consequently, when comparing an XLPE insulated cable to a PVC insulated cable of the same conductor size, the XLPE variant can handle a higher current load. This characteristic may allow for the selection of a smaller cable size based on your current load requirements when using XLPE insulation.

XLPE is more resilient than PVC due to its cross-linking process, which enhances its tensile strength, elongation, and impact resistance. Additionally, this process improves the material’s resistance to oil and chemicals, even at elevated temperatures, making XLPE a favoured choice for LSZH Flame Retardant or Fire-Resistant cables.

As a result, XLPE insulated cables are commonly used in main risers within buildings, as LSZH flame retardant and fire-resistant cables, and in applications extending beyond low voltage, including medium to extra high voltage scenarios.

Summary of Classifications:

| Polyvinyl Chloride (PVC) | Crosslinked Polyethylene (XLPE) | |

| Flexibility | Very easy to install | Slightly harder material |

| Current Load | Suitable for standard loads | Great for higher current load |

| Max. Operating Temperature | 70°C | 90°C |

| Short Circuit Temperature | 160°C | 250°C |

| Resistance to Heat Deformation | Poor | Good |

| Resistance to Solvent | Poor | Good |

| Resistance to Oil | Good | Excellent |

| Resistance to Organic Chemicals | Good | Excellent |

| Resistance to Inorganic Chemicals | Excellent | Excellent |

| Mechanical Protection | Good | Excellent |

| Density, g/cm³ | 1.4 | 0.92 |