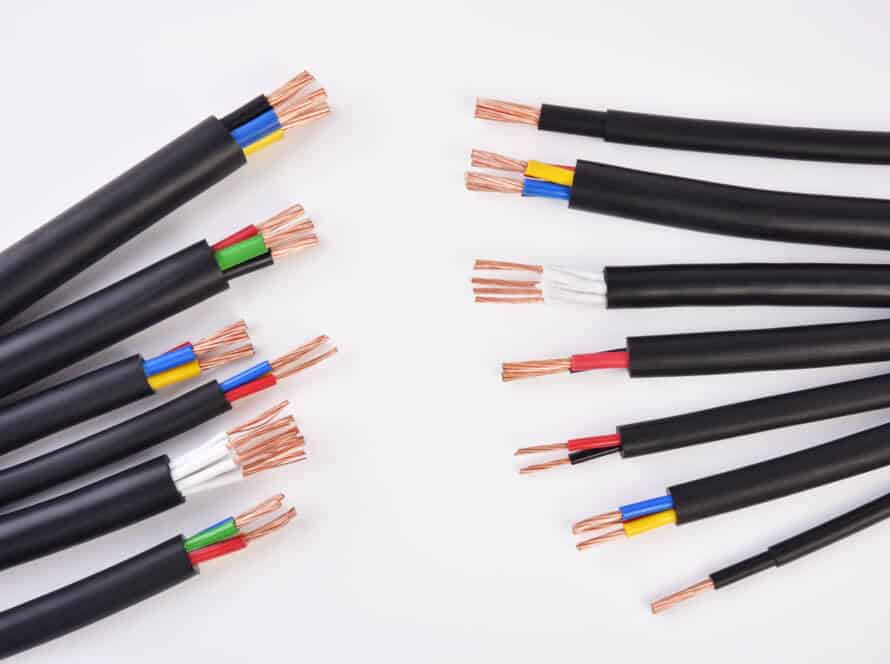

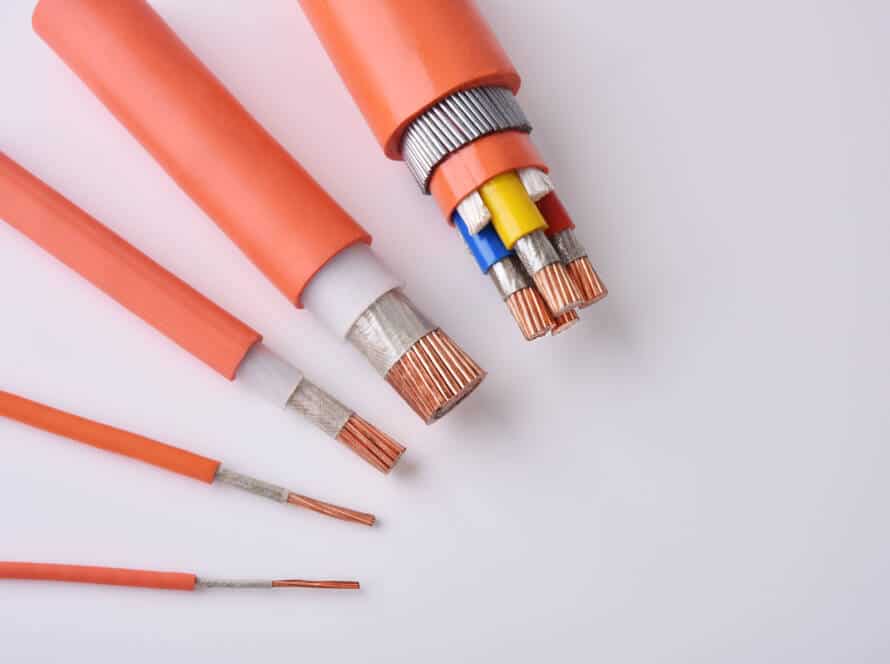

The conductor resistance (CR) test is fundamental yet crucial in the quality assessment of cables. This test serves to confirm whether the quantity and quality of the conductor material within a cable meet the necessary standards.

The CR test is conducted on either a full-length cable or a sample measuring at least 1 meter, in compliance with IEC 60228 standards. This test assesses the DC resistance of the copper or aluminium conductor, providing insight into the ease of current flow through the conductor; a higher resistance signifies reduced current flow. Excessively high resistance can lead to heat generation, potentially causing early insulation failure, which may result in a fire or short circuit.

The characteristics of the conductor, including its dimensions, construction, temperature, and resistivity, significantly impact the measured resistance (CR). Notably, due to the reading’s sensitivity to temperature variations, it is crucial to allow the sample to remain in the testing environment for an adequate duration. This ensures that the conductor’s temperature stabilizes, facilitating a precise measurement. Subsequently, the recorded resistance is adjusted to reflect an equivalent resistance at a standard temperature of 20°C, in accordance with IEC 60228, as well as the specified length.

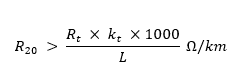

To verify that the conductor resistance complies with the required standard, the measured resistance Rt is evaluated in relation to the maximum allowable conductor resistance at 20°C (R20), where:

Rt = Observed Resistance

kt = Temperature Correction Factor (Table 1)

L = Length of the specimen in m

R20 = Maximum Standard Resistance at 20°C (Table 2)

When encountering a high conductor resistance reading (greater than R20), it is advisable to consider the following calculation adjustment factors before delving into potential conductor issues:

- The possibility of an inaccurate conductor temperature, as a temperature exceeding 20°C can lead to an elevated observed resistance (Rt).

- The potential for an incorrect cable length, since a longer cable can also contribute to a higher observed resistance (Rt).

If these factors are ruled out, one might need to consider:

- The purity of the conductor, particularly if the copper content is below 99.9%.

- The adequacy of the conductor’s quantity, which may involve thinner wires or a reduced number of strands, resulting in a diminished cross-sectional area.

At TONN Cable, we routinely perform the CR test on every finished cable to ensure compliance with international standards.