Cables are designed to transport electric current in a safe and efficient manner. However, the integrity of these safety and performance objectives can be jeopardized by the presence of counterfeit cables. Such imitation products may lead to various performance issues, including a reduced lifespan, as well as serious safety risks like overheating and an elevated likelihood of electrical shock or fire.

Counterfeit cables, by their very nature, falsely assert compliance with established safety and performance standards. This often involves misleading labelling that suggests adherence to specific international or national regulations, despite the fact that these cables do not meet the required criteria.

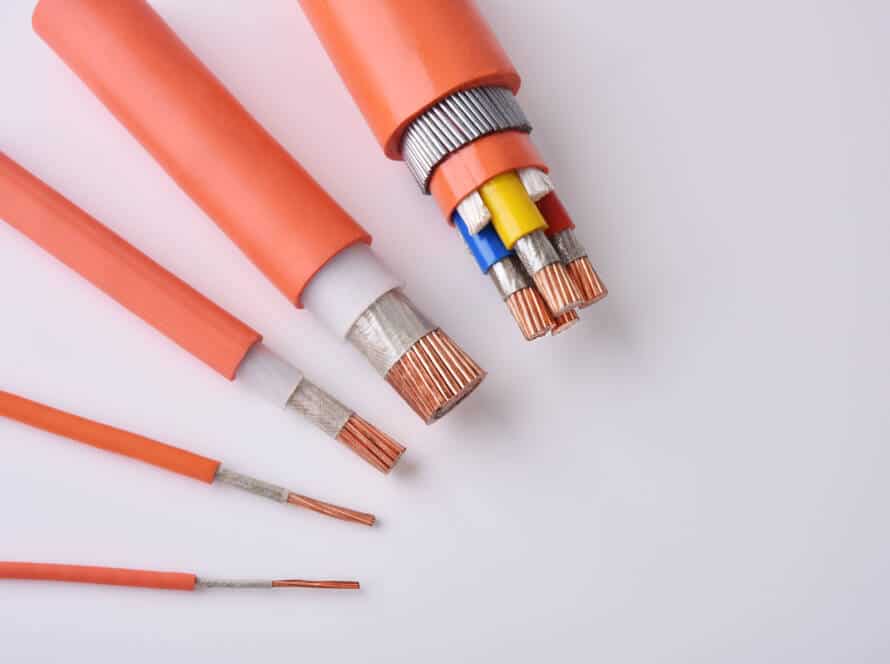

We have analysed the two fundamental elements that influence cable quality:

1) The material of the conductor

2) The materials used for insulation and the outer jacket.

Conductor

The quantity of copper is insufficient.

One of the most straightforward approaches to reduce cable production costs is to minimize the expense associated with the primary cost element, which is the copper conductor.

This can be achieved by either decreasing the cross-sectional area (CSA) of the copper conductor or by utilizing copper of lower purity.

Reducing the CSA can be done by either decreasing the number of strands or by diminishing the diameter of each strand in the conductor. Using impure copper involves employing material with less than 99.9% copper content, such as copper alloys or copper-plated aluminum. Both strategies will elevate the conductor’s resistance beyond the maximum limits established by relevant standards.

Conductors with increased resistance can present safety risks. The natural resistance leads to greater heat generation when current flows through the conductor. Additionally, the heat produced may lead to early failure of the insulation, potentially resulting in short circuits or even electrical fires.

How is the conductor tested?

Conductor resistance testing is utilized to assess the adequacy of the cross-sectional area (CSA) of copper conductors within a cable. A voltage is applied to a specific length of the cable, and the resulting current is measured. By applying Ohm’s law, the resistance of the conductor can be determined. If the resistance exceeds the established maximum threshold, it indicates that the CSA of the copper conductor is insufficient.

Insulation and sheath material

Subpar material composition

Similar to the conductor, inferior cables may arise from a decrease in both the quantity and quality of insulation materials employed. Insufficient quality of insulation can lead to a lower voltage rating. Additionally, cost-cutting measures may result in the inclusion of inferior additives in the insulation and/or sheath materials. This can lead to reduced flexibility of the cable, diminished insulation resistance, and an increased likelihood of cracking in the insulation or sheath over time.

Testing the insulation and jacket materials involves evaluating several key material properties. To provide a foundational understanding, we will focus on two critical types:

1) Insulation resistance pertaining to insulating materials

2) Mechanical properties

The insulation resistance test assesses the amount of current leakage from the cable, ensuring that the conductor is adequately insulated from external factors. Inadequate insulation can lead to short circuits, electric shocks, or even fires. Typically, this test is performed at the highest conductor temperature during standard operations. The type of material used for insulation and/or sheathing dictates this maximum operating temperature. A higher insulation resistance indicates superior insulation of the cable from its surroundings.

Tensile strength and elongation assessments evaluate the mechanical characteristics of the insulating and sheathing materials. The tensile strength of a material refers to the amount of force required to stretch it until it fractures. Elongation, on the other hand, indicates the extent to which the material can be extended before it ultimately fails.

The cable material undergoes testing at two distinct intervals. The first assessment occurs immediately following the cable’s production, while the second takes place after a period of accelerated aging, which involves exposing the material to predetermined temperature and duration conditions. Following this aging process, tensile strength and elongation tests are conducted again to evaluate the impact of aging on the mechanical properties of the materials.

Given the increased range of possible insulation and sheath challenges, it is essential to conduct additional tests to guarantee quality. We have outlined a fundamental set of essential tests performed on all cable types; however, further testing is necessary to verify that other asserted material properties are met. This encompasses evaluations of the cable’s fire resistance, water resistance, performance under thermal stress, and flexibility.

Overview

Counterfeit cables often assert that they meet international or national standards, yet they typically compromise on either the CSA of copper or the quality of insulation and sheath materials. Unfortunately, identifying a counterfeit cable directly is not feasible without comprehensive laboratory testing. Therefore, it is crucial to rely on the reputation of the cable brand you choose. Purchasing from a well-established brand that offers third-party certified products will help guarantee the durability and safety of your investment, alleviating concerns about premature replacement.