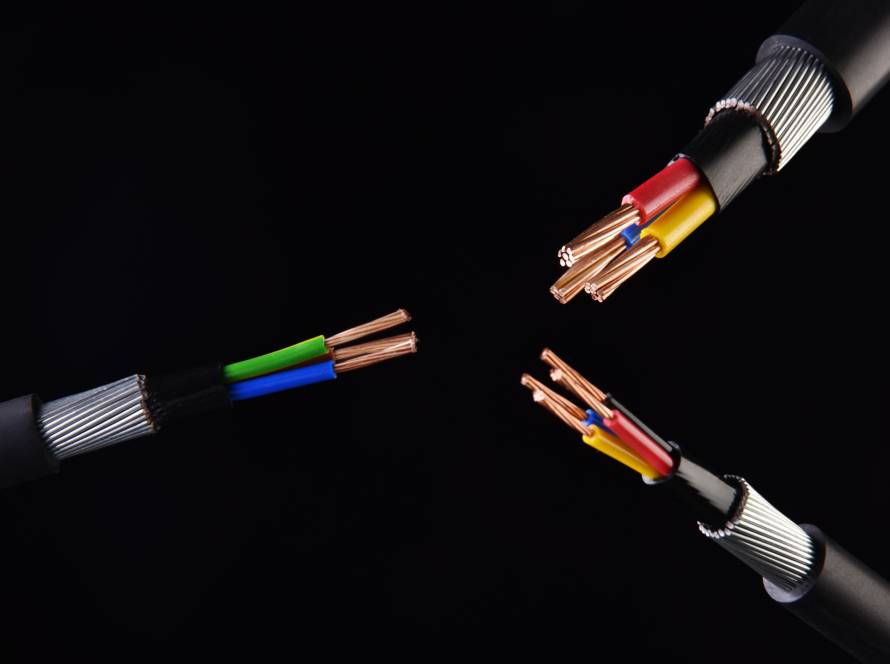

A cable conductor is the main element of electrical cables. It pertains to the metal wire or wires that transmit the electrical signal within the cable.

In this section, we explore the four distinct categories of Copper (Cu) conductors: Class 1, Class 2, Class 5, and Class 6.

What is the reason for the various categories?

Copper conductors are categorized based on their flexibility, with higher classes indicating greater flexibility. The flexibility of a copper conductor within a cable varies according to its specific application.

The most basic type of conductor is a single, solid wire (Class 1). While it provides a smaller diameter, the largest Cross-Sectional Area (CSA), and the clearest signal, it is mechanically fragile and susceptible to breakage after repeated bending cycles.

To enhance flexibility, wires are combined into strands. The greater the number of wires twisted together to achieve a specific size, the more pliable the conductor becomes. This indicates that a higher class corresponds to a greater number of strands within the conductor. Additionally, stranded wires are significantly easier to manipulate and bend during installation compared to a single wire of equivalent cross-section.

Here’s a detailed overview of each class:

Class 1: Solid Conductors

- Construction: Made of a single, solid copper wire.

- Flexibility: Rigid and inflexible.

- Applications: Typically used in permanent, stationary installations where the conductor will not be subject to frequent movement, such as in building wiring and power distribution.

- Characteristics: High electrical conductivity and resistance to corrosion, but less suitable for environments requiring flexibility.

Class 2: Stranded Conductors

- Construction: Composed of multiple smaller copper wires twisted or braided together to form a single conductor.

- Flexibility: More flexible than Class 1, allowing for some movement without breaking or damaging the wire.

- Applications: Used in situations where more flexibility is required, such as in circuits that may need to be bent, coiled, or moved occasionally.

- Characteristics: Offers a balance of flexibility and durability but may not be as conductive as a solid conductor of the same gauge.

Class 5: Flexible Conductors

- Construction: Consists of many fine copper wires (often tinned for corrosion resistance) twisted together, making the conductor highly flexible.

- Flexibility: Extremely flexible, designed for applications where the conductor needs to withstand frequent movement, bending, or vibration without damage.

- Applications: Often used in portable cords, flexible cables, and power tools that require a durable, yet highly flexible conductor.

- Characteristics: High flexibility, durable against wear and tear, but may have slightly lower conductivity compared to solid conductors due to the finer strands.

Class 6: Extra Flexible Conductors

- Construction: Made up of very fine copper wires, typically tinned, twisted into a very flexible configuration.

- Flexibility: The highest level of flexibility among copper conductors, suitable for applications requiring frequent movement or twisting.

- Applications: Used in highly flexible cable assemblies, robotics, and flexible power cables where the conductor will experience constant movement and mechanical stress.

- Characteristics: Very high flexibility, ideal for dynamic applications, but may have lower conductivity due to the fine strands.

Summary of Classifications:

| Class | Construction | Flexibility | Applications |

| Class 1 | Solid copper conductor | Rigid, non-flexible | Permanent installations, power distribution |

| Class 2 | Stranded copper conductor | More flexible than Class 1 | Applications requiring moderate flexibility |

| Class 5 | Fine stranded copper conductor | Highly flexible | Portable cords, power tools, flexible cables |

| Class 6 | Extra fine stranded copper conductor | Extremely flexible | Dynamic applications like robotics, flexible power cables |

These classifications help determine which copper conductor is most suitable for specific applications, based on factors like flexibility, durability, and electrical conductivity.