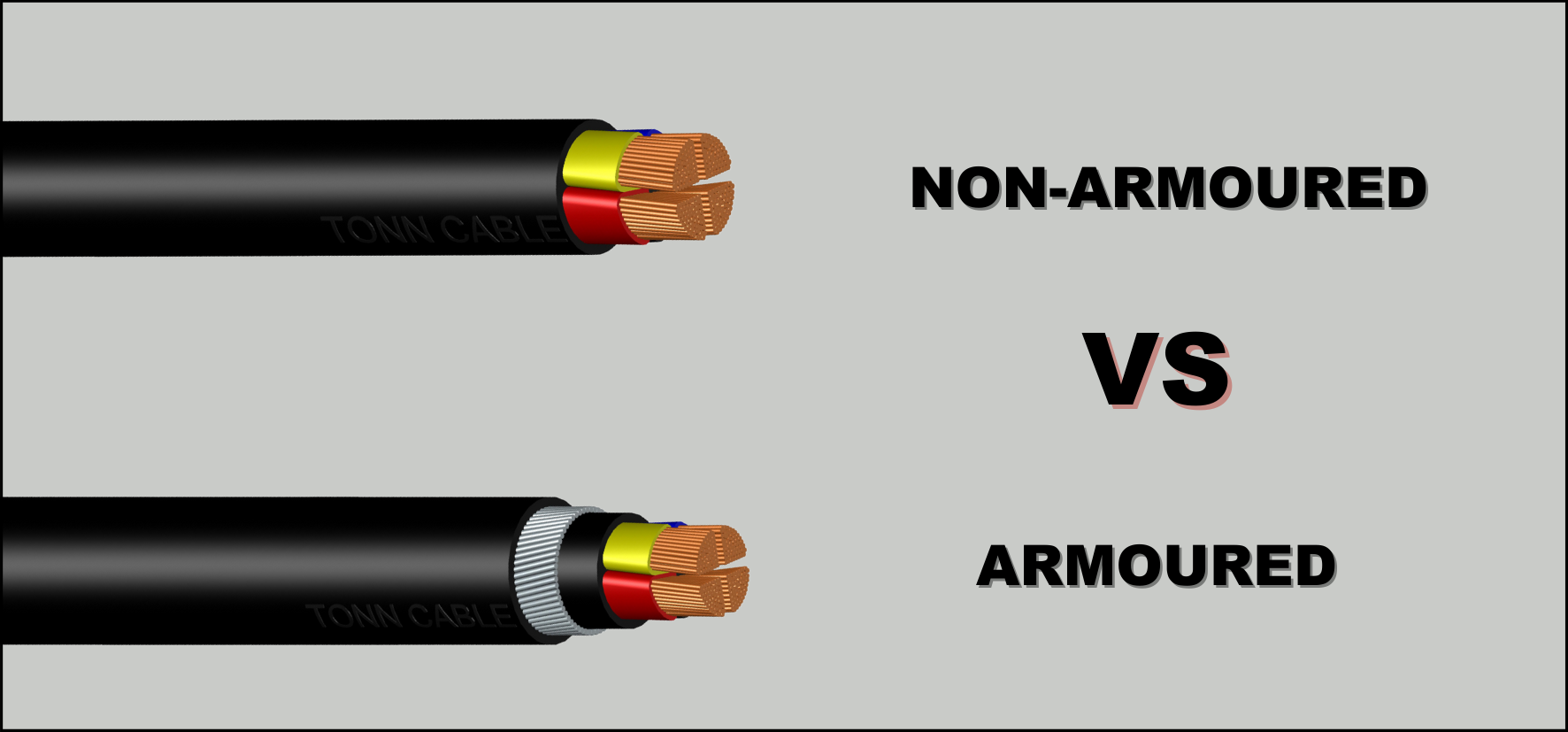

What distinguishes unarmoured cables from armoured cables?

The distinction between unarmoured and armoured cables lies primarily in the protective features of the latter. Armoured cables are equipped with an additional layer of protective armour, which serves to safeguard the cable core from potential damage. This added protection is particularly crucial in environments where the cable may be subjected to mechanical stress or impact. For instance, armoured cables are often utilized in scenarios where they need to be installed underground or within tunnels. In situations where the ground is excavated, there is a risk that tools such as spades or mechanical excavators could inadvertently strike the buried cable. In such cases, the armour plays a vital role in shielding the cable conductor core, thereby reducing the likelihood of exposure, electric shocks, and disruptions in power supply.

Aluminium wire armour (AWA) and steel wire armour (SWA) are both commonly used for standard power cables. While steel is inherently a more robust material, it is important to observe that single-core cables are consistently equipped with AWA rather than SWA. This preference is due to the non-magnetic properties of aluminium.

What distinguishes AWA from SWA in the context of armoured cables?

When a single-core cable is equipped with steel wire armour, the flow of current generates a magnetic field, effectively turning the entire cable into a large magnet. The intensity of this magnetic field increases with the current, leading to the induction of eddy currents in the steel. This phenomenon can result in overheating and significant derating of the cable. In contrast, aluminium, being non-magnetic, does not present this challenge.

In the case of two or more core cables, it is permissible to use galvanized steel wire armour again. This is because the magnetic fields generated by the multiple cores tend to cancel each other out, thus mitigating the effects of magnetic flux.

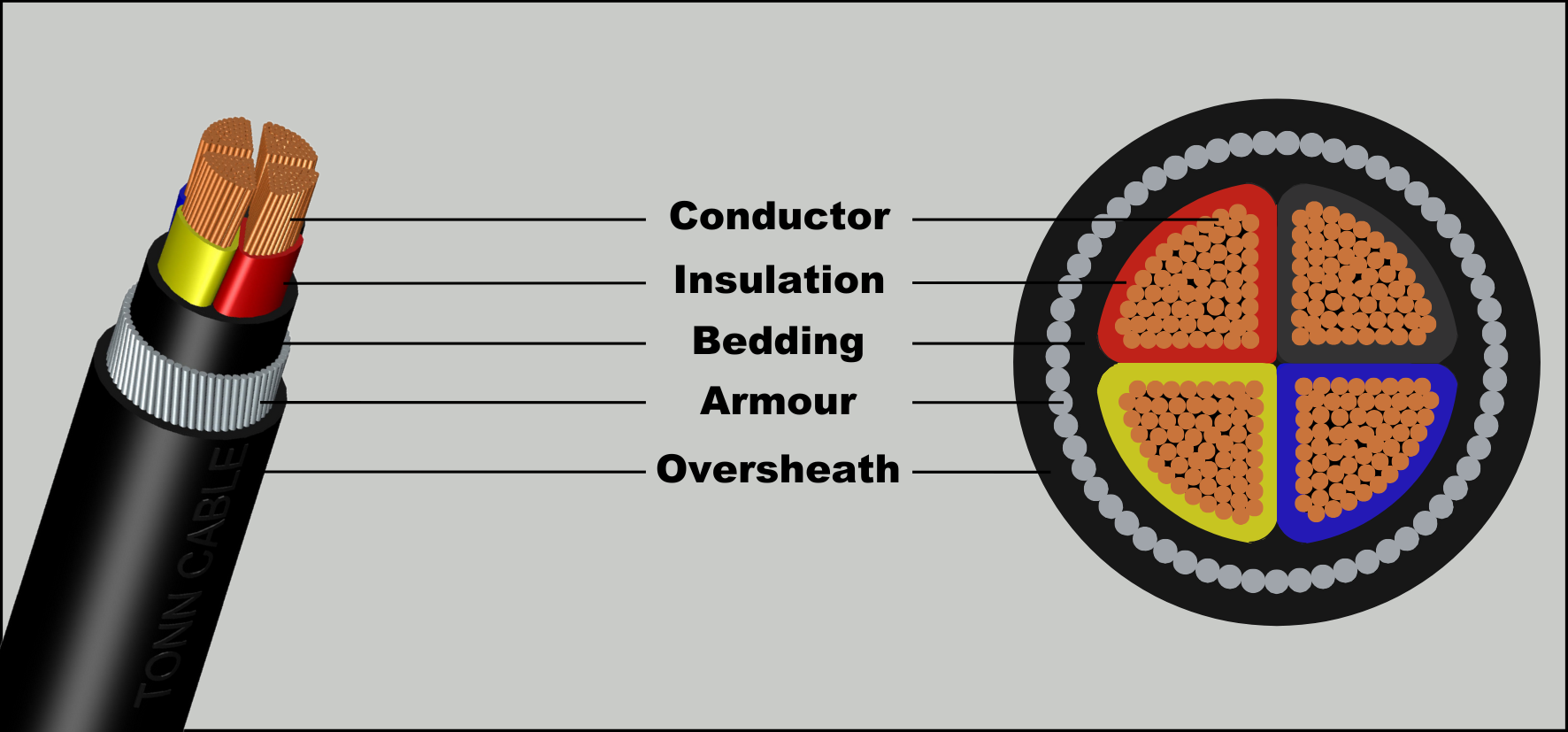

Conductor

Class 2 stranded plain annealed copper is utilized.

Insulation

Cross-linked polyethylene (XLPE) is preferred over polyvinyl chloride (PVC) due to its superior maximum operating temperature, enhanced water resistance, and improved dielectric characteristics.

Bedding

This layer serves as a protective barrier between the insulation and the armour.

Armour

Mechanical protection is provided by steel or aluminium armour.

Sheath

The outer sheath, made of PVC or LSZH (Low Smoke Zero Halogen), secures the cable. LSZH is particularly advisable for use in public spaces or tunnels.